Seems every project for these tanks fights me but I guess thats the draw. Once its figured out and working I'm like, ok now whatDo you ever have a reef project that seems to fight you every step of the way? That's this project for me. I finally got all my PVC glued together yesterday and even though I marked everything, the return line was a problem. I was worried it would get too short on me since the PVC always goes together easier once the glue has been applied, but I ended up being a 3/8" too long which doesn't sound like much but it is the difference between two halves of a union sitting flush with one another versus angled, which will leak. I finally got that all worked out this morning and I added a second union above the return pump. In the end, I'd like to say it's better, and it will be for cleaning the pump, but I panicked when I glued the last of the pipe together and assembled it quickly for test fitting while the glue was still not set. It turns out that I didn't have the return pipe in the right position, it was angled more than I had planned for originally, so I cut the pipe to try to fix it before I realized my mistake. Measure twice, cut once, make sure every piece is marked and then trust yourself that you did it right.

I also had to take the bulkheads loose and reconfigure the emergency overflow 3D printed holder. there wasn't enough clearance between the 4" filter sock and the overflow to easily replace the sock. It was OK before and everything was marked, so I don't know what I did differently, but 6 hours of printing later, problem solved. I'm leak testing the overflow section again now and all is well so far.

I've also backed off the idea of using two sea swirls for returns. I'm just going to use one and then keep my two MP10's in the mix. I'll save the second one as a backup. Testing the one sea swirl with this size tank seems to be enough to cover the majority of the tank (90 degrees of movement) without shooting water directly into the overflow. This tank has to support SPS, LPS, and zoas / palys so I want some areas of the tank to have less flow than others. I'm going to pull my 40W UV sterilizer for now and leave it out of the system, the problem with it is that it's a little too oversized to allow for lower maintenance levels of UV treatment unless I routed the return line through the UV also. I didn't want that level of commitment with the older unit I have.

I'm going to apply a black vinyl static cling sticker to the back of the tank next instead of painting it. The goal is still to have the tank in place before the end of the day tomorrow, but still a long way to go including clearing my office out and breaking down the 40 gallon. My clowns are going to be upset because they just laid fresh eggs Thursday afternoon. I'm going to see if I can move them all to a 10 gallon temporarily to save the batch.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cook's 80g Seapora Frag tank

- Thread starter Cook

- Start date

Here is where I am as if this morning. Everyone went to the trough yesterday morning except for the clowns that are in a 10 gallon with their eggs. Most everything is reconnected hardware wise and ready for filling back up tonight. I did uncover a rather depressing vermitid snail population hidden among the live rock. I’m must have missed a hitchhiker at some point. Since this rock was all dry to start with.

which is worse? Vermitid snails or gray asterina starfish? I have some live Pukani I could swap this rock out with, but it’s full of starfish. Leave a comment.

which is worse? Vermitid snails or gray asterina starfish? I have some live Pukani I could swap this rock out with, but it’s full of starfish. Leave a comment.

asterinas are easier to get rid of than vermitid snails

So I gave this subject some thought and I decided to dig the vermitids off the rocks with a magnifier and a scalpel. The only thing I could think of worse than vermitids was vermitids and asterinas. It was only 5 rocks and they weren’t deep in the rocks yet. I’m keeping an eye out for signs of repopulattion.

I’m trying to take care of at least one thing a day on this tank. Today was build the screen top, which I had put off for far too long. This is the Red Sea DIY kit. I forgot how much I hated making these screens. The tool that comes with the kit for applying the spline is difficult to use. Looks good in the end though.

Funny enough, I was watching the BRS top screen top mistakes video and they do not like the red sea spline tool either, they recommend a cheap tool from one of the home improvement stores, should have watched earlier!

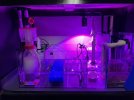

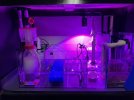

Since my last post, I got my refugium online (far right) and adjusted a few things. The way I hard plumbed the refugium, it creates bubbles and surges when the flow tries to create a siphon. I drilled a hole in the top of the 90 and inserted a piece of hard airline which helped. I turned the flow down on the pump as well. I like the sump layout. I added a Aquamaxx reactor for GFO and moved the calcium reactor return to the sponge filter section.

I’m still using my 36” Aquatic Life Hybrid with a Mithras 7206. I have been gathering the pieces for the new lights over the last month or so. I bought a 48” T5 Hybrid Noopsyche from @scottw and I will be adding two Reefi UNO’s to it next week to gain the coverage I need. Bulbs arrive tomorrow, will be 2x Blue Plus, 1x Coral plus, 1x Actinic.

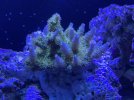

Here is a pic of my Walt Disney that has finally grown over the whole 3D printed plug and is starting to take off. I just moved a Homewrecker frag from QT this week also to try that one again. I almost forgot, I got RR Orange Passion from @jcook54 last month too, so my must have SPS’s for this tank are covered.

Here is a pic of my Walt Disney that has finally grown over the whole 3D printed plug and is starting to take off. I just moved a Homewrecker frag from QT this week also to try that one again. I almost forgot, I got RR Orange Passion from @jcook54 last month too, so my must have SPS’s for this tank are covered.

Where did you get your stand? I think I’m going to setup another 80 frag tank.

@scottw got me the replacement part for the hanging kit and I got it and a PAR meter from Pure Reef Saturday. This is the result and the Nooppsyche Hybrid looks great. These Reefi UNO lights are capable of a lot of PAR, 60 percent output results in 200 par on the bottom. I currently have them 13” off the water.

Looks fantastic!!

- Messages

- 113

- Reaction score

- 38

Nice, been looking for Sea Swirl for cheap and cant find any.

It’s been OK so far with some ups and downs. My clowns are spawning again which seems to coincide with GHA outbreaks, so ugly tank but happy fish. I haven’t had a chance to try to tweak the spectrum on the uno’s yet. I QT’d a cole tang and had him in the tank for about a month before I noticed he had disappeared. I don’t know what happened, but he died, all I found were the bones when I was moving some frag racks, and no one else was affected. He was eating well at the time also.

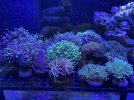

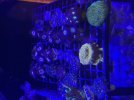

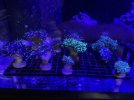

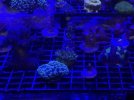

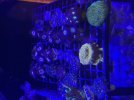

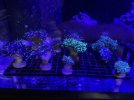

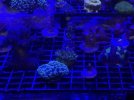

Some pics of a few of the frag racks.

The tank is due for a cleanup and I intend to swap the Fiji rock for some Pukani now that I think I have gotten rid of the asterina starfish they were covered in. If they survived me not feeding them since the summer and living the winter in the unheated garage then I suppose they deserve to live.

The tank is due for a cleanup and I intend to swap the Fiji rock for some Pukani now that I think I have gotten rid of the asterina starfish they were covered in. If they survived me not feeding them since the summer and living the winter in the unheated garage then I suppose they deserve to live.

Similar threads

- Replies

- 0

- Views

- 449