Lesson learned here. I’m going to double up on my tank equipment redundancy.

Everything seems to be a okay, yesterday I came home and figured out what caused the failure of power bar.

I had connected power bar to a new smart plug before my trip, to verify wattage. Well silly me forgot to program smart plug to stay on as default setting. When power tripped that put it to sleep.

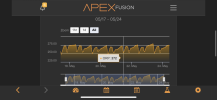

btw I did use seachem alk buffer yesterday (8 table spoons) it raised alkalinity by .3dkh but now it back down to 7.7

btw I did use seachem alk buffer yesterday (8 table spoons) it raised alkalinity by .3dkh but now it back down to 7.7

Both calcium reactors been running over night, tank is hungry. I’ll use 8 more table spoons

Still waiting on lights to come on to see how many corals were lost.

Everything seems to be a okay, yesterday I came home and figured out what caused the failure of power bar.

I had connected power bar to a new smart plug before my trip, to verify wattage. Well silly me forgot to program smart plug to stay on as default setting. When power tripped that put it to sleep.

btw I did use seachem alk buffer yesterday (8 table spoons) it raised alkalinity by .3dkh but now it back down to 7.7

btw I did use seachem alk buffer yesterday (8 table spoons) it raised alkalinity by .3dkh but now it back down to 7.7Both calcium reactors been running over night, tank is hungry. I’ll use 8 more table spoons

Still waiting on lights to come on to see how many corals were lost.