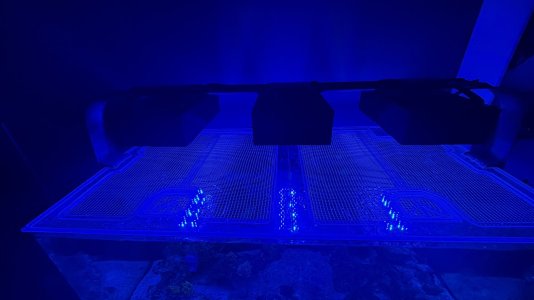

I decided to make my own screen lid because all of the commercially available ones are so expensive. I think it turned out pretty good. It’s made from polycarbonate, which is stronger than acrylic and doesn’t bend as much. I do an advantage of having a CNC machine but there was definitely some trial and error. Glad I didn’t ruin the 1 sheet I got!

I decided to make my own screen lid because all of the commercially available ones are so expensive. I think it turned out pretty good. It’s made from polycarbonate, which is stronger than acrylic and doesn’t bend as much. I do an advantage of having a CNC machine but there was definitely some trial and error. Glad I didn’t ruin the 1 sheet I got!You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My DIY Lid

- Thread starter Tigresteve09

- Start date

Amazing im planing to do one too i have a friend with a cnc i might try one what do you use to make it vcarve?

Yes, I used Vcarve. .25” polycarbonate from Amazon. I ended up buying a 0 flute plastic bit but you maybe could use an upcut bit. Definitely cannot use a downcut. The downcut melts the chips.

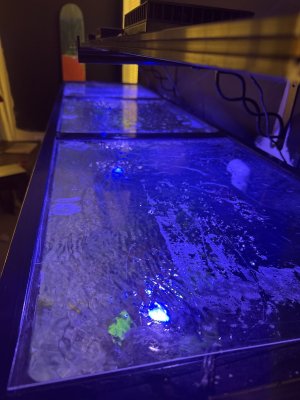

I have found poly to warp and curl fairly quickly, would be interested to see how yours does, maybe it’s a certain type I have. I have it in my freshwater tank to slow the evaporation. See pics

On my reef tanks I use this super cheap plastic sheet from hobby lobby. It’s strong, light and easy to cut and although flexible, likes to stay flat as a board. It can be a little brittle so drilling might not work but a cnc would make quick work of it I’m sure. At $7 for a large sheet it well priced

On my reef tanks I use this super cheap plastic sheet from hobby lobby. It’s strong, light and easy to cut and although flexible, likes to stay flat as a board. It can be a little brittle so drilling might not work but a cnc would make quick work of it I’m sure. At $7 for a large sheet it well priced

- Messages

- 222

- Reaction score

- 12

How did you cut the sheet to fit your tank?I have found poly to warp and curl fairly quickly, would be interested to see how yours does, maybe it’s a certain type I have. I have it in my freshwater tank to slow the evaporation. See pics

On my reef tanks I use this super cheap plastic sheet from hobby lobby. It’s strong, light and easy to cut and although flexible, likes to stay flat as a board. It can be a little brittle so drilling might not work but a cnc would make quick work of it I’m sure. At $7 for a large sheet it well priced

View attachment 107577

View attachment 107578

Acrylic warps more than polycarbonate. I also made it in 2 pieces for my 4ft tank. Looking at the retail lids, it appears they all use multiple pieces for larger tanks.

I used .25 inch polycarbonate which is actually 0.22inches. I wouldn’t go any thinner and 0.375” would probably be best but what it was double the price.

The 4ft x 2ft piece I got was $70 from Amazon. Then I used aquarium screen, which I also found on Amazon and then routed a dado and used screen spline just like you would for a screen door. Again, that’s how all the retail lids are made.

I used .25 inch polycarbonate which is actually 0.22inches. I wouldn’t go any thinner and 0.375” would probably be best but what it was double the price.

The 4ft x 2ft piece I got was $70 from Amazon. Then I used aquarium screen, which I also found on Amazon and then routed a dado and used screen spline just like you would for a screen door. Again, that’s how all the retail lids are made.

I may be open to making them for others but it would have to think about what the cost would be. The actual cutting isn’t too much time or work, it’s the design that can take a while. For example, the trial and error and testing for the light mount cutout.Would you cut one for someone else if they supplied the sheet?

If you didn’t have lights that were tank mounted, it would be much easier.

Hmmmm. I forgot about the light mounts needing to clear. Luckily its just a 6' HMS rail run along the tank with only two small points of contact and powerhead wires. I would just need it cut out. I could install the screens.

My lids - no holes - I have a sump full of macros and none of my corals seem to be upset from being cut off from the outside world. A few benefits of this setup - keeps heat in and stable, keep evap down, keeps stuff out. Right now I don’t have any fish to keep in but that would be the other benefit. Cut that plastic with a Stanley knife so no fancy tools needed either.

If I felt I ever needed to aerate I could do that via the sump

Everything’s puffy and happy

If I felt I ever needed to aerate I could do that via the sump

Everything’s puffy and happy

a solid top has its benefits, like evaporation, but would make feeding and maintenance a lot more cumbersome for me.My lids - no holes - I have a sump full of macros and none of my corals seem to be upset from being cut off from the outside world. A few benefits of this setup - keeps heat in and stable, keep evap down, keeps stuff out. Right now I don’t have any fish to keep in but that would be the other benefit. Cut that plastic with a Stanley knife so no fancy tools needed either.

View attachment 107584

If I felt I ever needed to aerate I could do that via the sump

View attachment 107585

Everything’s puffy and happy

It’s a 6ft tank? I would do 3 2ft pieces. I’d it rimless? And for the light mount cutouts, if you don’t go pretty “exact” around it, any gaps would be big enough for jumpers to make their way out…. At least that’s what I read.Hmmmm. I forgot about the light mounts needing to clear. Luckily its just a 6' HMS rail run along the tank with only two small points of contact and powerhead wires. I would just need it cut out. I could install the screens.