Hey Guys,

So first off I want to make it clear that I have no Idea what I am doing.

A few weeks ago I came across a post on another reefing Forum of a individual that created his own DIY Reef Monitor. After reading through the post, I thought the idea was extremely interesting and I wanted to give it a shot. I have a background in the ATM Industry and used to manage a small tech repair center, so I have a basic knowledge of electronic components and how they all function. I built a DIY PH Monitor and overall that seemed to work perfectly fine, so I figured why not give it a shot and put my limited knowledge to the test. Everything I know about electronic components is self-taught, and I have received 0 training.

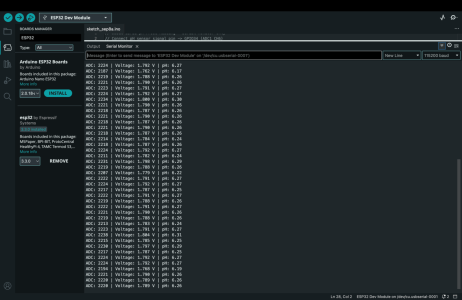

My Goal: To create a Alkalinity Monitor that records ALK 4 Times a Day and sends me email notifications of the results collected. Once I get this device functional, I plan to incorporate a 2 part dosing unit that will dose 2 part based off the results it collects. I will be using AI to help design, code, and troubleshoot the entire process, and to showcase some of the capabilites of implementing AI for DIY Projects.

I am on no Timeframe to get this done, so there may be some weeks I have multiple updates, and there are going to be some weeks where I may not work on it all. My schedule is pretty busy, however I really wanted to document this process because I thought others may find it interesting!

For anybody that is thinking about trying this themselves my recommendation is wait until I finish before starting your own. I will be posting by trial and error, so im sure there will be mistakes in the process.

Lets see how this goes!

So first off I want to make it clear that I have no Idea what I am doing.

A few weeks ago I came across a post on another reefing Forum of a individual that created his own DIY Reef Monitor. After reading through the post, I thought the idea was extremely interesting and I wanted to give it a shot. I have a background in the ATM Industry and used to manage a small tech repair center, so I have a basic knowledge of electronic components and how they all function. I built a DIY PH Monitor and overall that seemed to work perfectly fine, so I figured why not give it a shot and put my limited knowledge to the test. Everything I know about electronic components is self-taught, and I have received 0 training.

My Goal: To create a Alkalinity Monitor that records ALK 4 Times a Day and sends me email notifications of the results collected. Once I get this device functional, I plan to incorporate a 2 part dosing unit that will dose 2 part based off the results it collects. I will be using AI to help design, code, and troubleshoot the entire process, and to showcase some of the capabilites of implementing AI for DIY Projects.

I am on no Timeframe to get this done, so there may be some weeks I have multiple updates, and there are going to be some weeks where I may not work on it all. My schedule is pretty busy, however I really wanted to document this process because I thought others may find it interesting!

For anybody that is thinking about trying this themselves my recommendation is wait until I finish before starting your own. I will be posting by trial and error, so im sure there will be mistakes in the process.

Lets see how this goes!